Mastering Commercial Fire Sprinkler Installation Procedures with Armor Fire Protection

Implementing commercial fire sprinkler systems effectively is paramount for safeguarding lives and valuable assets. This is achieved through meticulous design, strict adherence to codes, and superior craftsmanship. Facility managers and business owners face increasing demands to meet NFPA 13 standards, ensure system performance, and manage long-term expenses. This comprehensive guide outlines the essential system types, detailed installation phases, component selection criteria, regulatory integration, and the cost-benefit analysis involved in mastering fire sprinkler installation procedures with Armor Fire Protection. You will gain insights into the distinctions between wet pipe, dry pipe, pre-action, and deluge systems, understand the planning and permitting processes, learn how to select appropriate sprinkler heads, valves, and piping, grasp the significance of NFPA compliance, and recognize how proper installation drives enhanced safety, insurance savings, and a strong return on investment.

What Are the Key Types of Commercial Fire Sprinkler Systems?

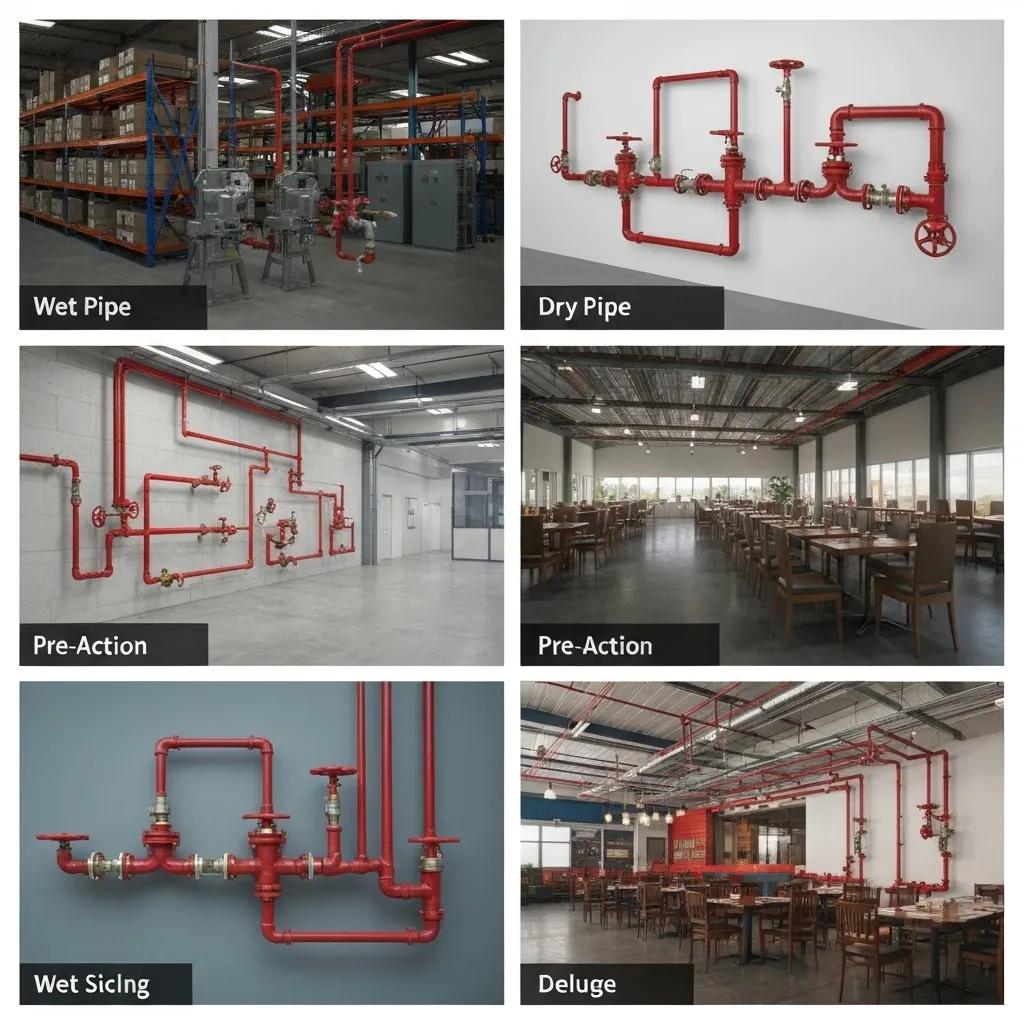

Commercial fire sprinkler systems are distinguished by their activation medium, response speed, and suitability for various environments. The selection of the optimal system hinges on factors such as building usage, local climate conditions, and the specific hazard classification of the area.

Fire Sprinkler Systems: A Guide to Design and Installation – English

Fire sprinkler systems are classified according to their activation mechanisms, including wet pipe, dry pipe, pre-action, and deluge systems. Each system is engineered for particular applications, taking into account building use, climate, and hazard classification. The chosen system significantly influences the installation procedures and the selection of components.

International Code Council, Fire Sprinkler Systems: A Guide to Design and Installation (2018)

Each system type offers a unique balance of response time, freeze protection, and risk management, forming the foundation for tailored installation strategies.

How Do Wet Pipe Systems Work and When Are They Installed?

Wet pipe systems maintain a constant water-filled state within the piping. When a heat-sensitive element, such as a glass bulb or fusible link, activates, water is immediately discharged. This straightforward and reliable design simplifies installation, making it ideal for climate-controlled environments. For instance, a retail establishment benefits from the rapid response of a wet pipe system without the need for complex operational controls.

What Are the Features of Dry Pipe and Pre-Action Systems?

Dry pipe systems utilize pressurized air within the pipes to prevent freezing in unheated areas. Water is only released once the air pressure drops, signaling valve activation. Pre-action systems incorporate an additional detection interlock to prevent accidental water discharge, making them suitable for protecting sensitive and valuable equipment. Both of these system types necessitate more intricate controls and piping configurations, leading to a higher degree of installation complexity compared to standard wet pipe layouts.

When Should Deluge and Other Specialized Systems Be Used?

Deluge systems are designed to flood an entire area simultaneously through open nozzles once a fire detection system is triggered. This provides rapid and extensive coverage for environments with high-hazard risks, such as chemical processing plants or aircraft hangars. Other specialized systems, like foam-water or water mist systems, are employed when conventional water-only suppression is insufficient. These systems demand precise calibration and sophisticated piping networks for effective operation.

How Do System Types Affect Installation Procedures?

The specific type of sprinkler system dictates distinct design workflows, material requirements, and control mechanisms. Systems designed for freeze protection, for example, require air compressors and solenoid-operated valves, while pre-action systems incorporate dual sensors and supervisory alarm functions. Understanding these variations is crucial for ensuring the correct integration of components and maintaining compliance throughout the entire process, from initial planning to final commissioning.

What Are the Essential Steps in Fire Sprinkler Installation Procedures?

The installation of fire sprinkler systems follows a structured sequence of five core phases, ensuring optimal performance, regulatory compliance, and unwavering reliability for commercial projects.

- Design & Planning – Conduct thorough hazard assessments, perform precise hydraulic calculations, and develop detailed layout models to ensure comprehensive coverage.

- Permitting & Approvals – Prepare NFPA 13-compliant drawings and obtain official sign-off from the local fire marshal.

- Pipe & Fitting Installation – Install main lines, branch lines, and hangers precisely according to the engineered design specifications.

- Head & Valve Configuration – Mount the appropriate sprinkler heads, verify K-factors, and integrate control and alarm valves seamlessly.

- Testing & Commissioning – Execute rigorous flow, pressure, and alarm tests, followed by a final inspection and certification.

How Is the Design and Planning Phase Conducted?

The design and planning phase commences with a comprehensive site survey and hazard assessment to accurately determine the occupancy classification and evaluate the available water supply. Sophisticated hydraulic calculations are then performed to establish precise pipe sizes and pressure requirements, often utilizing specialized software such as SprinkCAD or AutoSPRINK. Detailed CAD layouts subsequently define the exact locations for hangers, branch lines, and sprinkler head spacing.

What Permits and Regulatory Requirements Must Be Met?

The permitting process involves submitting detailed plans that clearly demonstrate compliance with NFPA 13 standards, any applicable local amendments, and seismic bracing requirements where necessary. Official approval from the fire marshal confirms that the proposed system adheres to all relevant building codes and occupancy-specific regulations. Engaging with regulatory authorities early in the process can significantly expedite inspections and minimize costly design revisions.

How Is On-Site Installation Executed for Pipes, Heads, and Valves?

On-site installation crews meticulously install main and branch lines using approved steel or CPVC piping, securely fasten hangers at specified intervals, and conduct pressure testing before proceeding with sprinkler head installation. Sprinkler heads are carefully mounted at designated elevations and orientations, while control and alarm valves are strategically positioned for easy access and integrated into the building’s alarm systems. Ensuring proper alignment and leveling is critical to prevent leaks and guarantee prompt system responsiveness.

What Are the Testing and Commissioning Procedures?

The commissioning process rigorously verifies the system’s readiness through a series of systematic tests. Main drain flow tests confirm adequate water supply, trip tests evaluate valve operational integrity, and alarm function tests ensure seamless integration with detection systems. A final inspection conducted by a qualified engineer or the authority having jurisdiction officially authorizes occupancy and issues the necessary compliance certificate.

Which Components Make Up a Fire Sprinkler System and How Are They Selected?

A fire sprinkler system is comprised of several critical components, including sprinkler heads, an intricate piping network, essential valves, alarm devices, and water supply controls. Each element must be carefully selected to precisely match the design specifications, environmental conditions, and hazard levels of the facility to ensure reliable activation and effective suppression.

What Types of Sprinkler Heads Are Used and How Are They Chosen?

The selection of sprinkler heads is a critical decision that balances coverage area, temperature rating, and the K-factor (flow rate). Pendent heads are designed for downward spray patterns under ceilings, upright heads are used for exposed piping, sidewall heads are ideal for narrow corridors, and ESFR (Early Suppression Fast Response) heads deliver high-volume discharge for demanding storage applications. Choosing the correct type of sprinkler head is essential for maximizing suppression performance.

How Are Piping and Water Supply Systems Designed and Installed?

Piping materials, such as schedule 10/40 steel, CPVC, or coated fittings, are specified based on project codes and water chemistry considerations. Piping layouts are meticulously designed according to hydraulic calculations to maintain optimal flow rates and pressure. Hangers and seismic bracing are installed to securely support the piping network. In situations where municipal water pressure is insufficient, a fire pump or a gravity tank may be incorporated into the system design.

What Role Do Control Valves and Alarm Systems Play in Installation?

Control valves are essential for regulating water supply and isolating specific zones for maintenance or repairs. Tamper and flow switches are integrated into the building’s alarm systems to provide immediate notification. Supervisory signals alert facility managers to any changes in valve positions or potential leaks. Proper placement of control valves and accurate wiring of alarm systems are fundamental to ensuring system reliability and maintaining code compliance.

How Does Compliance with NFPA 13 Impact Fire Sprinkler Installation?

NFPA 13 establishes the definitive minimum requirements for the design, materials, installation, and acceptance testing of fire sprinkler systems, all aimed at ensuring the highest levels of life safety and property protection. Strict adherence to these comprehensive standards guides every decision made during the installation process, from the spacing of sprinkler heads to the methods used for pipe support.

NFPA 13 Standard for the Installation of Sprinkler Systems – English

The National Fire Protection Association (NFPA) sets the industry-leading standards for the design, installation, and ongoing maintenance of fire sprinkler systems, prioritizing life safety and property protection. These standards encompass a wide range of critical aspects, including occupancy classifications, required design densities, and precise pipe sizing methodologies. Upholding NFPA 13 compliance is absolutely vital for guaranteeing the effectiveness and reliability of fire sprinkler systems.

National Fire Protection Association, NFPA 13: Standard for the Installation of Sprinkler Systems (2022)

What Are the Key NFPA 13 Installation Requirements?

NFPA 13 meticulously outlines requirements for occupancy classifications, design densities, pipe sizing tables, minimum pressure criteria, hanger spacing guidelines, and seismic bracing protocols. It also specifies the necessary documentation, the creation of shop drawings, and the qualification levels required for both system designers and installers.

How Are Local Codes and Fire Marshal Approvals Integrated?

Local building codes often include amendments that modify the baseline rules established by NFPA 13. Integrating these local requirements necessitates thorough plan reviews, pre-installation meetings with relevant authorities, and staged inspections throughout the installation process. Securing fire marshal approvals confirms that the system’s components and installation methods fully align with municipal ordinances and occupancy permits.

Why Is Ongoing Compliance Important for Safety and Insurance?

Maintaining continuous compliance through regular inspections and testing, as mandated by standards like NFPA 25, is crucial for preventing system failures and mitigating potential liability. Insurance providers frequently offer reduced premiums for facilities with approved and actively maintained sprinkler systems. Documented maintenance records are also invaluable for supporting business continuity plans and successfully navigating regulatory audits.

What Are the Cost Factors and Benefits of Commercial Fire Sprinkler Installation?

The investment in a commercial fire sprinkler system encompasses costs for materials, labor, design services, permitting fees, and testing procedures. These expenditures are significantly offset by substantial returns in enhanced safety, reduced insurance premiums, and improved operational resilience.

What Influences the Cost of Fire Sprinkler Installation?

Key factors influencing installation costs include the complexity of the system type, the total building square footage, the chosen piping materials, the required sprinkler head density, and the accessibility of the installation site. Systems such as pre-action or dry pipe designs typically involve higher material and labor costs compared to standard wet pipe systems.

How Do Fire Sprinklers Enhance Life Safety and Property Protection?

Fire sprinkler systems have a proven track record, successfully containing fires in approximately 96% of activation incidents. They significantly reduce property damage by up to 50% and lower injury rates by as much as 60%. The capability for early fire suppression provides critical time for occupant evacuation and minimizes the duration of business interruptions.

How Can Installation Reduce Insurance Premiums and Business Interruptions?

Insurance companies commonly provide substantial premium discounts, often ranging from 10% to 20%, for commercial properties equipped with approved fire sprinkler installations. The rapid control of fire incidents minimizes operational downtime and associated recovery expenses, thereby preserving revenue streams and maintaining stakeholder confidence.

Armor Fire Protection combines extensive NFPA expertise, comprehensive end-to-end service, and an unwavering commitment to safety to deliver turnkey fire sprinkler installations that elevate protection levels and optimize cost-effectiveness. Contact our dedicated specialists today to request a personalized proposal or schedule a site assessment for your upcoming project.

Explore Our Fire Sprinkler Services

Ready to Enhance Your Fire Safety?

Discover how Armor Fire Protection’s expert fire sprinkler services can protect your business. We offer comprehensive solutions tailored to your specific needs.