Mastering Backflow Testing: Your Gilbert AZ Compliance & Safety Guide with Armor Fire Protection

Backflow is a serious threat to your potable water supply, and understanding it is absolutely essential for every property owner and manager in Gilbert. This comprehensive guide breaks down the mechanisms of back-siphonage and backpressure, outlines crucial local and state testing obligations, and details the common prevention devices vital for fire lines, irrigation systems, and domestic services. You’ll discover why annual testing is non-negotiable for both public health and legal compliance, how our certified backflow testing is meticulously performed, and precisely what documentation Gilbert municipalities require for proof of compliance. We also cover common device failure modes, provide practical inspection and maintenance workflows, and demonstrate how a certified provider like Armor Fire Protection expertly handles reporting and necessary repairs. Throughout this guide, we’ve strategically included key terms like backflow testing Gilbert AZ, Gilbert backflow prevention, and certified backflow tester Gilbert to ensure you can easily find the services you need and make truly informed decisions about your property’s compliance and safety.

Understanding Backflow: Why Gilbert AZ Demands Critical Testing

Backflow is the dangerous, unwanted reversal of water flow that can introduce hazardous contaminants directly into your potable water system. This occurs when pressure in a downstream system either exceeds or suddenly drops below the supply pressure, forcing non-potable water back into your service lines. This critical mechanism poses a direct threat to public health, allowing dangerous substances like fertilizers, chemicals, or even sewage to mix with your drinking water. This is precisely why municipalities mandate stringent prevention and regular verification. Proactive testing identifies failing seals, stuck check valves, and relief valve faults before contamination can occur, significantly reducing your liability and safeguarding our community’s water quality. Annual verification, performed with meticulously calibrated testing equipment, stands as the primary control employed by certified backflow testers in Gilbert to rigorously protect our local potable water supplies.

For immediate, expert local support, Armor Fire Protection Inc. proudly offers certified backflow testing services right here in Gilbert. Contact us today to request a comprehensive quote or schedule your essential verification. Our highly certified team is ready to assist with thorough testing, accurate reporting, and any necessary next-step repairs.

The Root Causes of Backflow: Understanding the Threat to Your Water Safety

Backflow primarily stems from two critical causes: backpressure, which occurs when downstream systems generate higher pressure than the incoming supply, and back-siphonage, a dangerous phenomenon where supply pressure drops suddenly, drawing contaminants inward.

Common triggers for these hazardous events include heavy fire hydrant use, sudden pump startups, active irrigation booster pumps, and municipal main breaks that create abrupt low-pressure conditions.

Crucially, when cross-connections exist—those vulnerable points where potable and non-potable systems intersect—these events can allow dangerous pesticides, chemicals, or biological contaminants to infiltrate your distribution system. Detecting these hazardous conditions early through routine inspection and certified testing is paramount to preventing severe public-health incidents and avoiding costly emergency remediation.

Effective backflow risk management, therefore, hinges on accurately identifying all cross-connections and ensuring that prevention devices are not only appropriately selected but also meticulously maintained. This directly underpins Gilbert’s stringent regulatory requirements for testing and documentation.

The Non-Negotiable Importance of Regular Backflow Testing: Health, Safety & Legal Compliance

Regular, certified testing is your assurance that backflow prevention assemblies are functioning precisely to specification. It also provides legally admissible records that property owners and regulatory authorities absolutely rely on for demonstrating compliance.

During annual tests, our technicians meticulously exercise springs, check discs, relief valves, and test cocks to rigorously confirm that all pressure differentials and operational thresholds are met.

Without proper, documented tests, property owners face severe potential enforcement actions and significantly increased liability should contamination occur. Conversely, documented compliance is crucial for supporting insurance claims and fulfilling due-diligence obligations.

Consistent, professional testing effectively closes the critical loop between proper device selection, expert installation, and the long-term, unwavering water-quality protection mandated by local regulators.

Beyond compliance, routine testing also provides vital insights for timely repair decisions and optimal replacement timelines, thereby preserving your system’s integrity and ensuring full alignment with the rigorous cross-connection control expectations of the Town of Gilbert and the State of Arizona.

Gilbert AZ Backflow Regulations: Who Needs Testing & Why It Matters

Both Gilbert and Arizona regulations mandate robust cross-connection control programs, requiring annual verification of specific assemblies and the timely submission of test reports to the local water authority. These critical rules are designed to rigorously protect potable water quality and clearly assign reporting responsibility to property owners or their authorized agents. The Town of Gilbert municipal code and the Arizona Administrative Code precisely specify which assemblies and hazard categories demand inspection and testing, especially where fire protection, irrigation, or potential contaminants pose a risk. A clear understanding of which property types must comply empowers owners to prioritize essential testing and proactively avoid costly enforcement notices.

Below, you’ll find a concise mapping of common property classes and their typical regulatory obligations, designed to clearly outline your responsibilities for testing and reporting.

This table clearly illustrates that testing responsibility primarily rests with the property owner and must be diligently repeated annually to satisfy both Town and state program requirements. For property owners feeling unsure about proper filing or compliance, our professional, certified testers are here to expertly assist with all necessary paperwork and submission processes.

Gilbert’s Muni-Code: Your Backflow Testing Requirements Explained

The Town of Gilbert municipal code rigorously implements a local cross-connection control program, mandating the proper installation, diligent maintenance, and periodic testing of all approved backflow prevention assemblies wherever hazards are present. Specifically, the code mandates annual testing by a certified backflow tester, requires detailed test reports showcasing assembly serial numbers and precise measured pressures, and insists on timely repairs whenever failures are identified. Enforcement mechanisms are strict, including official notifications and potential service restrictions until full compliance is definitively established. Property owners are strongly advised to consult the local water authority for exact submission formats and deadlines, and always retain copies of all tests for their critical records.

A clear understanding of the local submission process significantly simplifies compliance and dramatically reduces enforcement risk. This is precisely why so many property owners wisely choose to partner with certified testers who are intimately familiar with Gilbert’s specific procedures.

Is Your Property Compliant? Annual Backflow Testing for Gilbert Commercial & Residential Sites

Several distinct property categories in Gilbert commonly require mandatory annual backflow testing. These include commercial properties with connections to potential contaminants, residential properties featuring irrigation or booster pump systems, multi-family housing with shared utilities, and any site equipped with a fire suppression connection.

Key examples encompass restaurants with intricate food-handling processes, medical offices housing labs, car washes, and properties that utilize fertilizers or chemical injectors for their irrigation systems.

Each unique scenario presents a distinct hazard level, which in turn dictates the precise type of backflow prevention assembly required and the specific testing frequency mandated by local authorities.

Property owners must proactively inventory all potential cross-connections on their site and strategically prioritize assemblies for annual testing to ensure continuous compliance and robust protection of potable water supplies.

Our Certified Process: Armor Fire Protection’s Backflow Testing in Gilbert

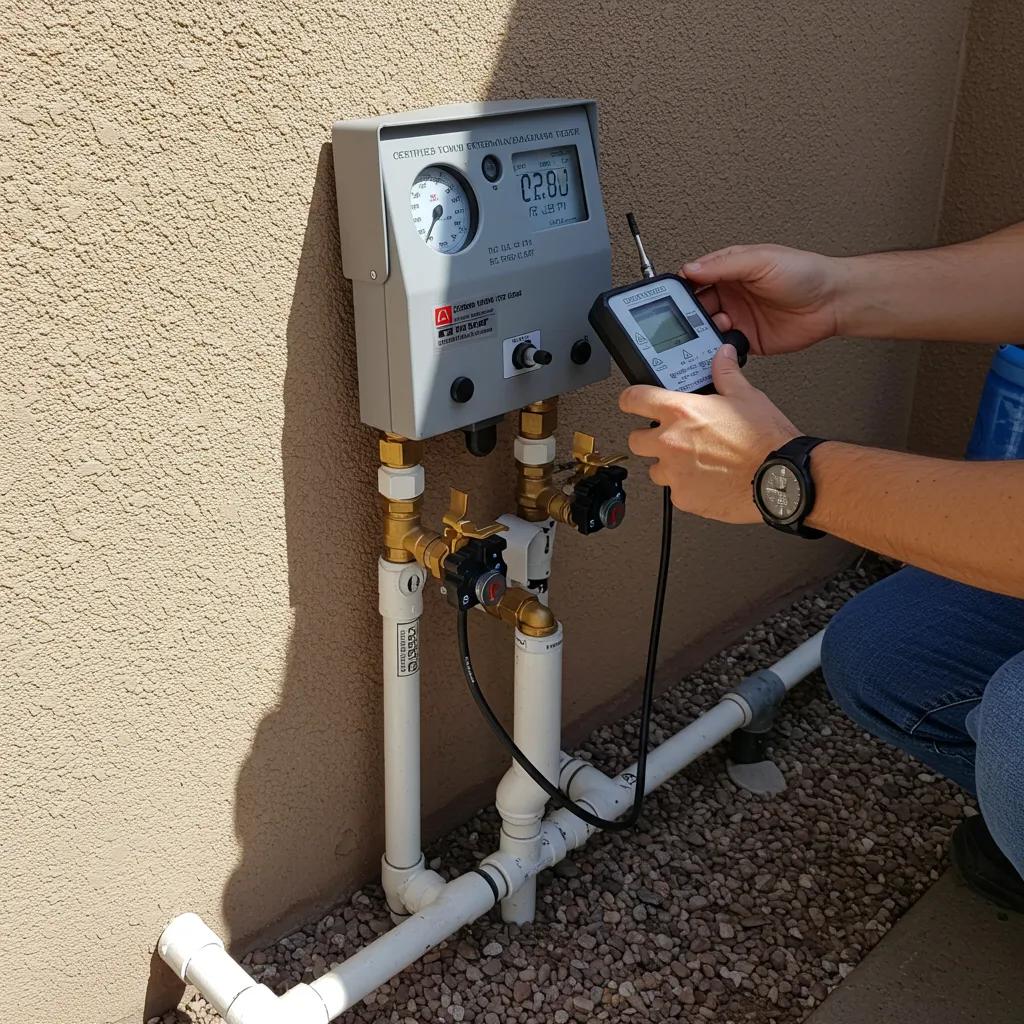

At Armor Fire Protection, our certified backflow testing adheres to a meticulously structured process: beginning with efficient scheduling and a thorough pre-inspection, followed by precise on-site identification and isolation of the assembly, then calibrated test procedures expertly performed by our certified testers, and culminating in complete, accurate documentation provided to both the customer and the water authority as required. We pride ourselves on fast turnaround times and leveraging our in-house resources. Our testers utilize state-of-the-art calibrated gauges and strictly follow accepted test sequences to accurately measure differential pressures and relief valve function. Your results will include a comprehensive, signed test report detailing measured values, clear pass/fail status, and any recommended repairs when necessary. Customers always receive copies of this crucial documentation, perfectly suitable for submission to municipal authorities to verify annual compliance.

Below, we provide a clear, step-by-step breakdown of our process, outlining expected customer deliverables and outcomes to fully illustrate your service path with Armor Fire Protection.

This detailed process table clearly outlines the practical deliverables you’ll receive and precisely how Armor Fire Protection expertly supports your critical reporting obligations here in Gilbert.

Our Backflow Testing Process: A Step-by-Step Guide from Armor Fire Protection

Our comprehensive testing process begins with efficient scheduling and a thorough pre-service checklist to confirm your device type and access requirements, ensuring seamless and efficient on-site work. Our certified testers then perform a meticulous visual inspection, safely isolate the assembly, and precisely attach calibrated test gauges to test cocks to accurately measure differential pressures and relief valve performance. All measured values are rigorously compared to stringent regulatory pass criteria, and any failing components are thoroughly documented with clear recommended repairs or replacements. The crucial final step involves preparing a comprehensive, signed, and dated test report, which we then provide directly to the property owner for their essential records or for seamless municipal submission.

Documenting & Reporting: Your Backflow Test Results to Gilbert Authorities

Immediately after testing, our certified tester meticulously completes a comprehensive test report. This report precisely lists the assembly type, serial number, all measured pressures, clear pass/fail status, and any required repairs. Crucially, the report is signed and dated, serving as a vital legal record. Depending on specific local practice, you will either receive a copy perfectly suitable for submission, or our tester can file the results directly with the water authority on your behalf, ensuring seamless compliance. Property owners must diligently retain all records to unequivocally demonstrate compliance during any inspections or audits. Prompt reporting and accurate documentation are paramount, significantly reducing the risk of enforcement actions and empowering owners to schedule necessary repairs before any service impacts occur.

Beyond compliance, clear and thorough documentation also robustly supports warranty claims or proactive maintenance planning, providing an invaluable compliance trail for all future property transactions.

Backflow Prevention Devices: Testing & Maintenance for Gilbert Properties

Gilbert properties typically utilize a range of essential backflow prevention assemblies, each meticulously tailored to specific hazard levels and applications. These include: Reduced Pressure Zone (RPZ) assemblies for critical high-hazard uses like chemical injection or fire lines; Double Check Valve Assemblies (DCVA) for robust protection against moderate hazards; and Pressure Vacuum Breakers (PVB) or Spill-Resistant Vacuum Breakers (SVB), ideal for irrigation and atmospheric conditions. Within each device, crucial components such as check valves, relief valves, and test cocks are rigorously inspected and tested for any leaks, proper spring condition, and accurate pressure differentials.

The table below is designed to help property owners easily match device types to their typical use-cases and understand the required testing cadence.

This clear comparison empowers property owners to confidently identify their specific assembly type and understand the essential maintenance required, thereby supporting more effective budgeting and proactive compliance planning.

Common Backflow Prevention Devices for Gilbert Properties: A Closer Look

RPZ assemblies offer the absolute highest level of protection and are critically installed wherever contaminants pose a significant health hazard, such as in commercial chemical applications and on many fire lines. DCVAs are compact and perfectly suited for moderate-hazard conditions where backpressure is the primary concern, frequently found in commercial domestic connections. PVBs and SVBs effectively protect against back-siphonage in irrigation systems. While simpler in design, they are sensitive to freezing temperatures and specific installation elevations. The suitability of each device hinges on a thorough hazard assessment, and only proper installation combined with diligent annual testing can truly ensure reliable, long-term performance.

Choosing the precisely correct assembly type and consistently scheduling routine, certified tests are paramount to significantly reducing failure risk and ensuring full alignment with all Town of Gilbert requirements.

Beyond Testing: Armor Fire Protection’s Expert Backflow Device Repair & Installation

Armor Fire Protection offers comprehensive on-site diagnosis, expert parts replacement, and full, professional installation services for all backflow prevention assemblies, always with meticulous attention to strict code compliance and thorough documentation. When our certified tests indicate that repair is necessary, our skilled technicians promptly source only approved replacement parts, expertly perform repairs or complete assembly replacements, and rigorously verify full functionality through retesting. All new installations strictly follow code-driven placement and meticulous permit coordination. Crucially, Armor Fire Protection’s dedicated in-house teams manage every aspect of testing, installation, and documentation, ensuring seamless service without any subcontracting. You will receive a comprehensive final test report and expert guidance on optimal maintenance intervals to proactively preserve your device’s peak performance.

For immediate repair or installation quotes, or to schedule your essential certified backflow testing in Gilbert, please contact Armor Fire Protection Inc. directly. Call us today at (480) 633-5922 or visit our local office at the listed Gilbert address to request a detailed, no-obligation service estimate.